Maximize Success During the Metal Roofing Boom Through Specifications

Metal roofing has been used in a variety of commercial buildings for years. Retail centers, office buildings, public facilities and industrial properties have benefited from metal roof’s long-term performance, energy efficiency and low life cycle costs. In addition, new styles and shapes that are possible by using metal materials are boosting metal roofing’s design popularity in both commercial and residential projects.

Metal roofing has been used in a variety of commercial buildings for years. Retail centers, office buildings, public facilities and industrial properties have benefited from metal roof’s long-term performance, energy efficiency and low life cycle costs. In addition, new styles and shapes that are possible by using metal materials are boosting metal roofing’s design popularity in both commercial and residential projects.

Today, more and more home owners are also considering metal roofing as an alternative to other traditional roofing options[1].

To take advantage of this growing market for metal roofing products, manufacturers need to begin to explore and evaluate their brand’s position in the specifications. Knowing more about how a brand is positioned with architects will help maximize success.

Facts of the Case

According to a 2019 research study recently published Roofing Contractor Magazine[2] 82% of contractors indicated they are currently involved with metal roofing. Many also indicated they see increased opportunity for growth in metal roofing, particularly in the residential market. More than half of respondents indicated their residential metal roofing sales increased in 2018 and 57% indicated they expected sales to increase in 2019.

The best way for manufacturers to take advantage of the growing metal roofing market is to strengthen relationships with architects and designers who specify metal roofing. Today, if a manufacturer is not on a firm’s “short list,” it is almost impossible to be listed in a project’s specifications.

Architects have many choices in brand when it comes to roofing. So it is even better for a manufacturer to be named as the projects’ “basis of design” or better yet, be listed as the brand with no substitutions or on the roofing schedule. Manufacturers need to start developing relationships with architects to provide them with the information they need to make better product selections. To do this, manufacturers must first understand the specification process and what factors are most important to the architect’s selection of metal roofing products. This will assure the architect that the manufacturer has the information and product details to meet their project objectives.

Many manufactures work hard to get their brand in the architect’s specification and to be included in the list of approved brands. For new manufacturers or existing manufacturers trying to get a new product into the specification can be a daunting task.

Architects and designers do not change or review their specifications often. In research conducted and published by Architect Magazine titled The Truth About Specification[3], many times architects re-use or revise existing specifications. In fact, the research found that only 26% write specifications from scratch and 57% end up using specifications from a previous project—sometimes using the specifications with no changes.

Adapt Change or Disappear

Where manufacturers can start to penetrate the specifications is to at least get on the “list” of brand options specified. Typically, architects are required to list “alternative” brands to help promote competitive bids/pricing. While being on the list is better than not, it still does not mean your product will be purchased.

Key Factors In Architect’s Selection of Metal Roofing Products

The key factors for architects can vary based on the project and the particular objectives of the architect’s client. According to research and an article published by Architect Magazine[4] titled How to Specify a Metal Roof for Commercial Buildings, there are several factors architects must consider when selecting a brand of metal roof.

Architects must not only consider product standards and performance requirements, but they also need to take into consideration other factors like the climate of where the project will be located, any local zoning requirements or the particular pitch or form the roof will need.

Many times, metal roofing is selected to obtain a certain “look” or aesthetics, which will need to be balanced with other goals of the project like functionality, energy savings, or even exposure to various types of weather. The more specific product information manufacturers can provide the architect, the better. They need specific information on how products can meet their project goals.

In fact, in reviewing metal roofing specifications there are very specific product requirements outlined by architects. For example, a metal roof product often needs to meet wind resistance, thermal performance and resistance to various temperatures.

Manufacturers need to outline and offer proof of product performance standards. Also, they must meet and deliver standards for packaging, delivery and warranties.

Installation requirements are often outlined in the specification. Accountability Information Management, Inc. (AIM) conducted qualitative one-on-one interviews with architects for a metal product manufacturer. Architects stressed that they will not specify a metal exterior product that does not have a history of product performance in the project location and type of project they are specifying.

In addition, an equal amount of importance was given to having trained, educated and experienced installers. To strengthen the relationship with architects, manufacturers should study the specifications of metal roofing so they can best address the key issues and factors impacting architect’s brand selection.

Specifications Analysis Helps Identify and Strengthen a Brand’s Position with Architects

AIM Architects’ Brand Preference Study revealed just how competitive the metal roofing market is. In this unaided blind brand preference study, architects and designers were asked to list their top three brands of metal roofing products.

There were over 27 brands or companies mentioned by architects that were “involved” with the specification of these products. Although the list of specific brands has no doubt shifted over time, the numerous choices they have to choose from still holds true[5]. Architects and designers have lots of brand choices when it comes to metal roofing products.

To help manufacturers evaluate their brand position in the marketplace, it is important to first understand more about an architect’s level of involvement when specifying metal roofing products. How much control or influence does the architect or designer have on selecting a particular brand of metal roofing.

Looking at metal roofing, the degree to which architects are involved in specifying a specific brand or manufacturer can vary. In AIM’s Architect’s Brand Preference research, only 32% of the architects surveyed indicated that they were involved in selecting and specifying the brand metal roofing products. Of those that were involved, 46% indicated they did not have a brand preference. This was a major decrease since previous research, which indicated only 15% had no brand preference. Could this be that the specification of metal roofing is increasingly complex and many architects delegate that other professionals like a structural architect or an architect specializing in materials or exterior building products?

While architects may indicate they have “no preference,” they are, in fact, involved in specifying and recommending the metal roofing products. The architect will weigh in on the type of look or performance they want to achieve.

However, due to the growing complexity of commercial projects, architects may delegate or collaborate the brand selection to “others” in the specification path. Many design firms today maintain a list of “approved” brands that have met specific performance and quality requirements. If a manufacturer is not on “the list,” the chance of being in a specification are limited. It is becoming increasingly important for manufacturers to expose and educate architects on their product features, benefits and other services they offer the market.

Becoming a brand on the architect’s preferred list of brands is key to impacting a brand’s position in the specifications. To be on a firm’s list of approved metal roofing brands, a manufacturer needs to provide more than just a quality product. They need to have a history of top performance, offer premiere service, local support for their brand and often a list of certified installers.

What should metal roof manufacturers do to enhance brand selection and preference? How can manufacturers convert “no preference” answers into specifications and recommendations for their brands? These are important questions.

Impacting Brand Specification with the “Basis of Design”

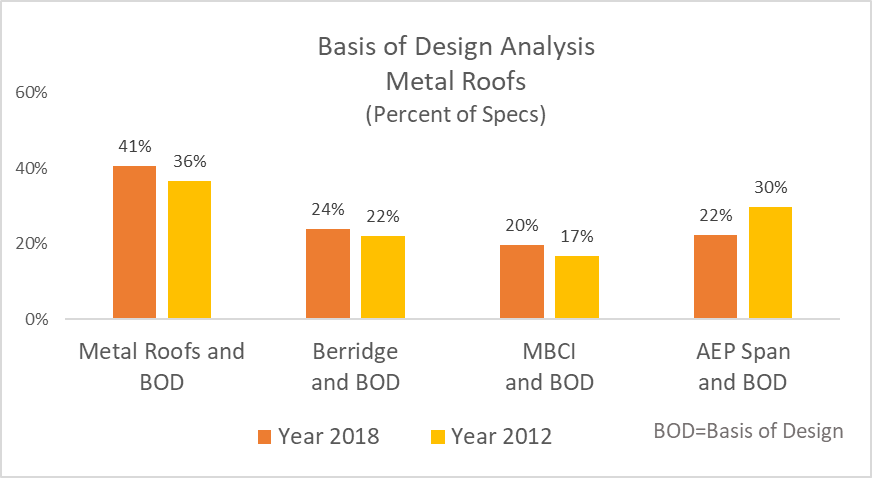

To answer these questions, consider what we know about specifications. The key to gaining ground in specifications is to become part of the “basis of design.”[6] This means that the architect or designer is calling out a specific brand that is used to meet the objectives of the project. To learn more about how often “basis of design” is used in metal roofing specifications, we used ConstructConnect™, (https://www.constructconnect.com/), an online construction database, to get a better sense of how metal roofing products are specified. By searching the projects roof specifications for “metal roof projects with Basis of Design,” in specific years, we can see how the specification for “basis of design” and specific brands has changed.

41% of projects in 2018 with a metal roof specification also included a brand as the “basis of design.” However, this has increased since 2012 where “basis of design” was specified in only 36% of the metal roof specifications.

There are many brands that are involved in delivering metal roof products to the market. This type of specifications analysis can show manufacturers how often their brand is specified as the “basis of design” and if it has shifted over a specific period of time.

The market is constantly changing and it is important for a manufacturer to continuously review their position in architect’s specifications. A manufacturer cannot always be sure that they are on a firm’s “preferred” list. They can, however, evaluate how often their brand appears in the specifications. They can measure how often they are the “basis of the design” or appear in the roofing schedule. A brand found in the specifications and labeled the “basis of design” is automatically on the list of “preferred” brands.

The same research can be done on the other product categories or on specific brands based on the manufacturer’s needs. AIM can design a specifications analysis to meet a client’s objectives and look at a particular brand/manufacturer, by territory, competitors, project type, location or by specifications area/schedule. Let us know where your interests are. Thank you.

[1] An expected increase in metal roofing sales in 2018 was 60 percent, the highest amount recorded by Roofing Contractor’s survey respondents since 2012. Roofing Contractor’s State of the Industry Report and Survey 2018, Roofing Contractor Magazine; February 2018.

[2] Roofing Contractor’s State of the Industry Report & Survey 2019; Roofing Contractor Magazine; February 2019.

[3] The Truth About Specification, by John Schneidawind, AIA highlights key findings on an AIA survey of 330 architects on how they select and specify building materials for commercial projects. The article stresses the importance of an architect’s relationship with building product manufacturers and report that 60% of the time the architect already knows which materials an architect is going to use. https://www.architectmagazine.com/aia-architect/aiafeature/the-truth-about-specification_o

[4] How to Specify a Metal Roof for Commercial Buildings, Architect, November 2017, https://www.architectmagazine.com/technology/products/how-to-specify-a-metal-roof-for-commercial-buildings_o

[5] Sweets, for example, lists only 11 manufacturers in the category “metal roofing.” However, in a recent specification for a mixed-use development in Julian California, there were 24 manufacturers listed for the metal roofing portion of the specification! Interestingly, six of the Sweet’s manufacturers were not even in that specification, which means 19 of the manufacturers in that specification were not in Sweet’s. Architects get their information in many ways, and it is important for the manufacturer of any product to make sure that they are in the architect’s line of sight.

[6] USlegal.com defines it as “Basis of design is a term used in engineering, which typically consists of text paragraphs, preliminary drawings, equipment lists, etc. Well-defined requirements consist of a set of statements that could form the basis of inspection and test acceptance criteria. The basis of design documentation and the specification identify how the design provides the performance and operational requirements of the project and its systems.”